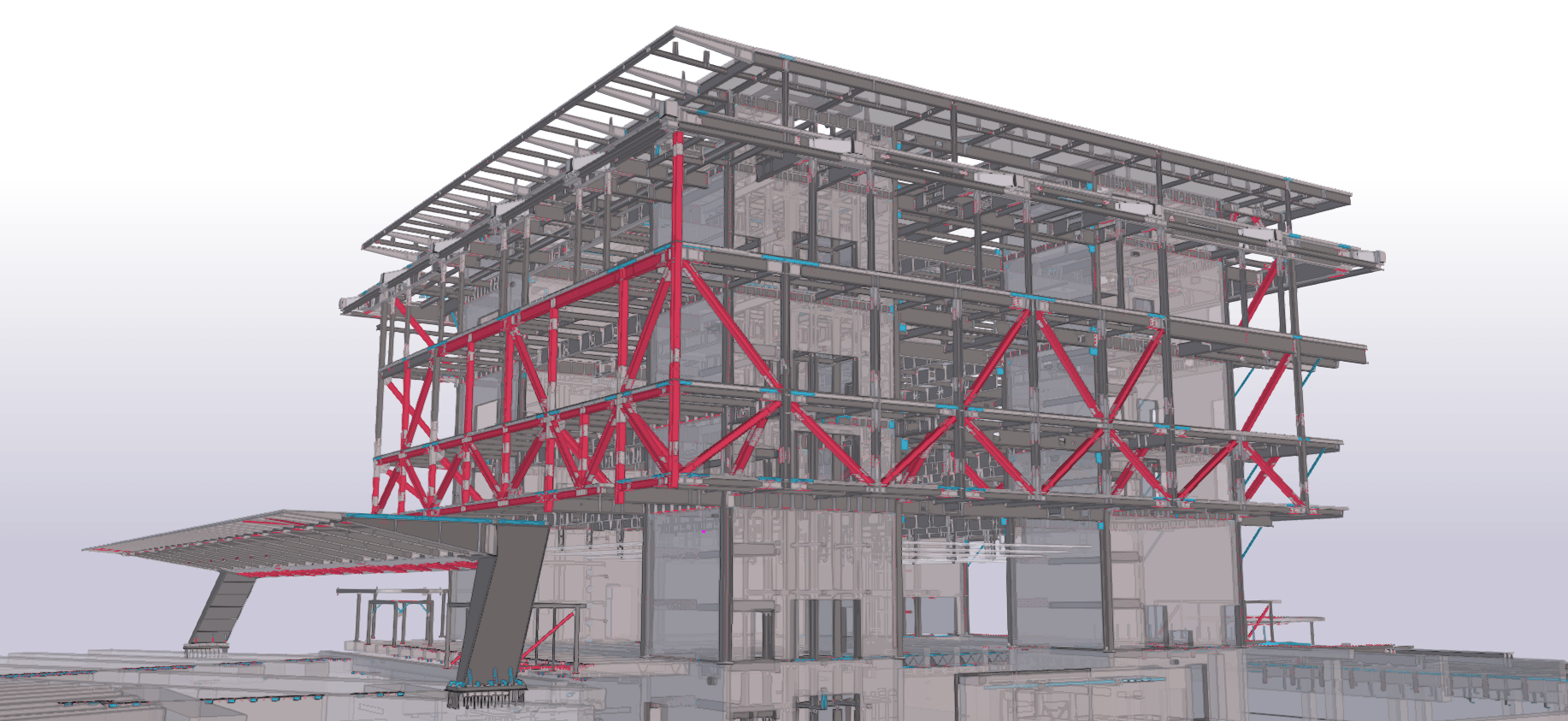

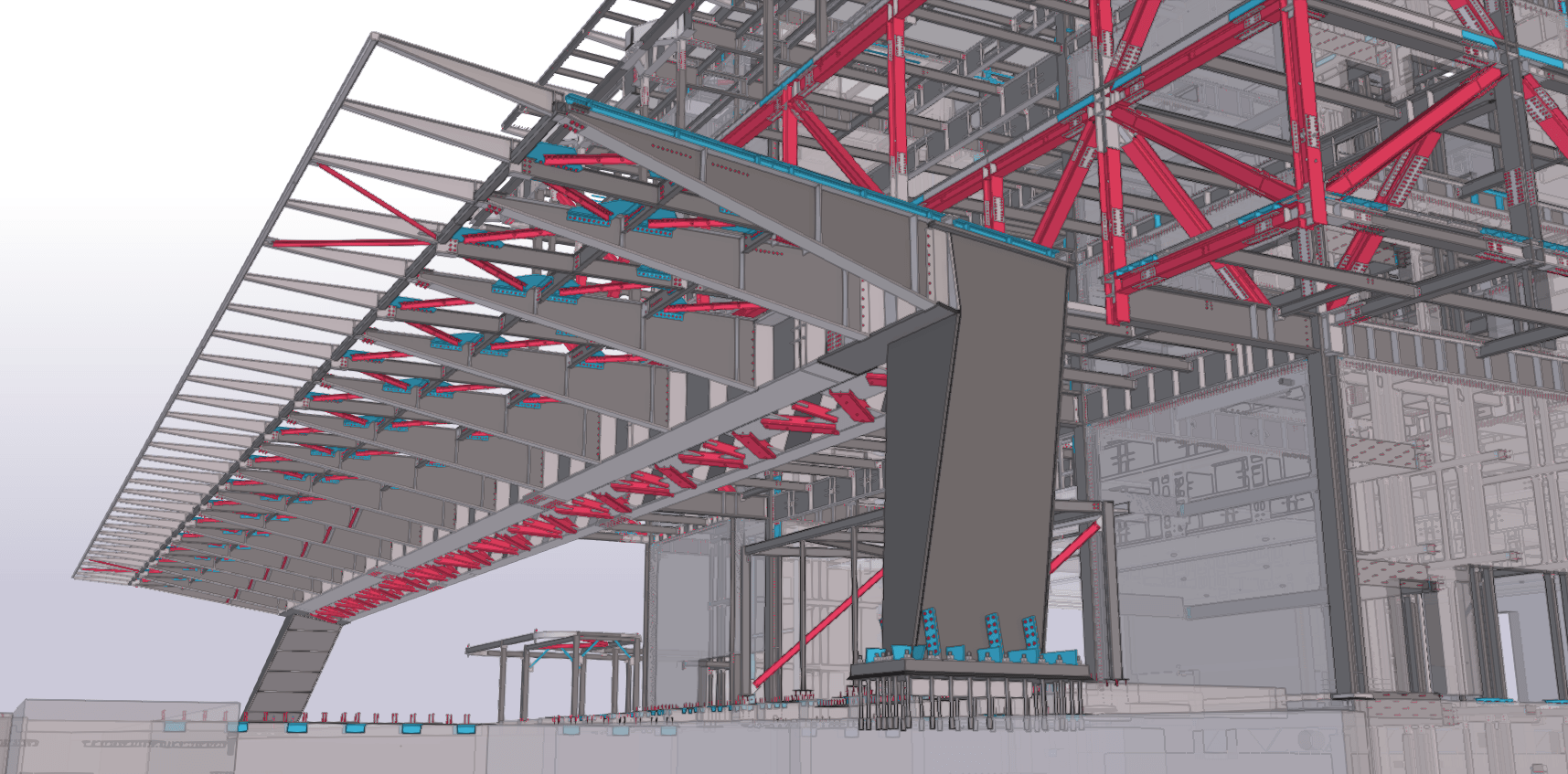

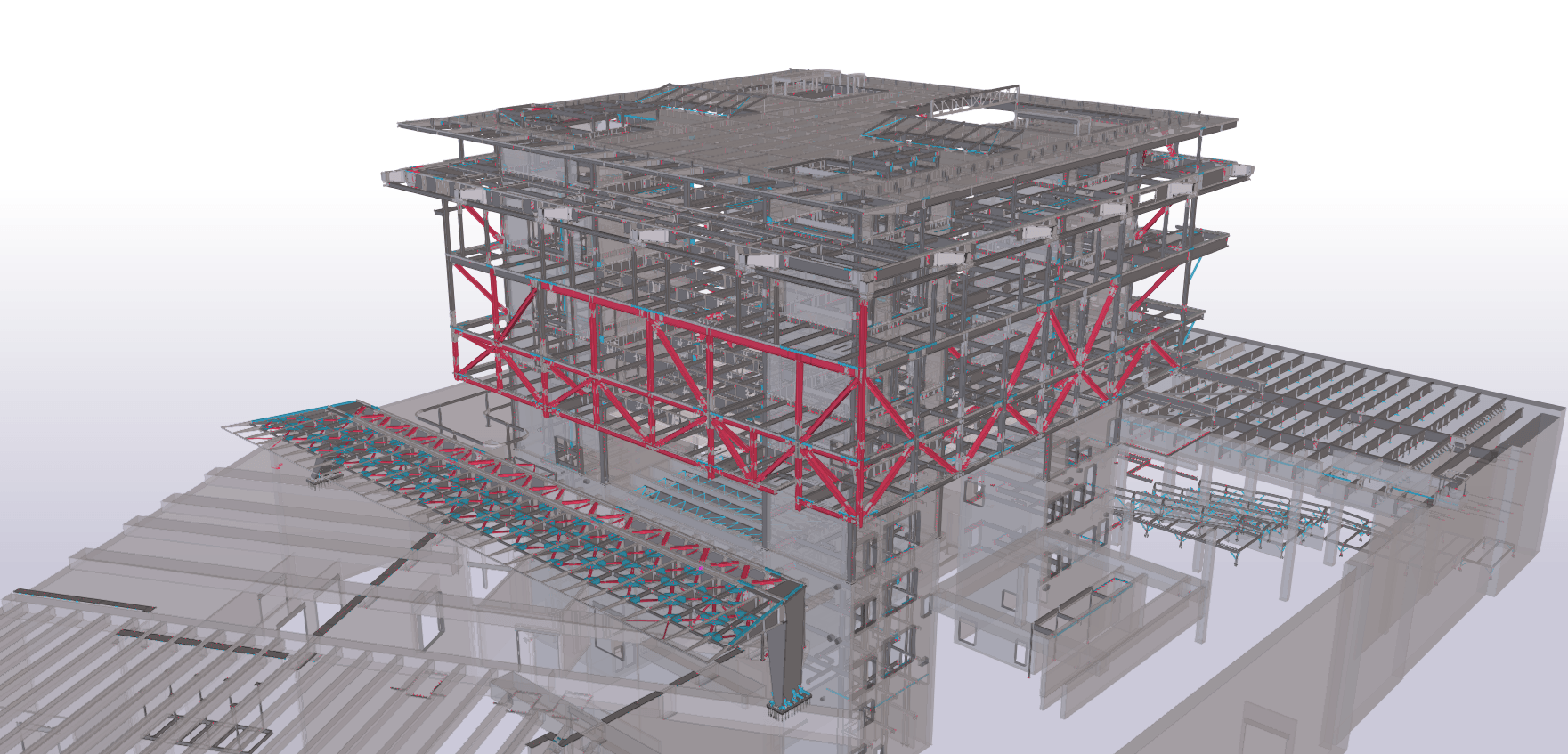

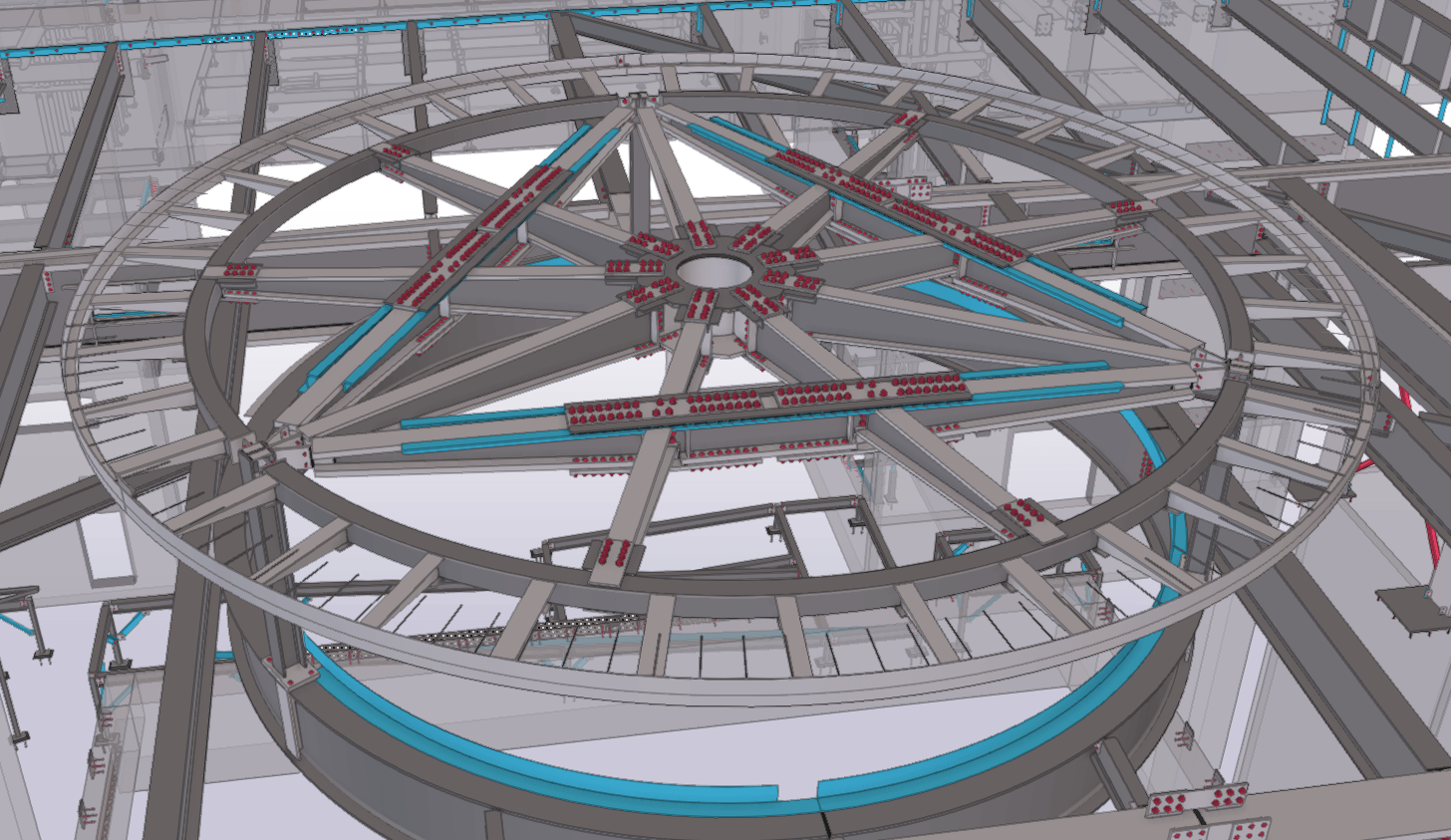

The Smithsonian National Museum of African American History and Culture consists of approximately 350,000 square feet. The three major components of design are the grand porch at the entrance from Constitution Avenue, the corona shape of the structure, designed to resemble a crown, and the bronze corona cladding around the building. The structural steel consists of heavy plate girders, box girders, box columns trusses, beams and columns. The four concrete core towers are linked at the top by steel trusses. The grand porch includes very heavy box columns and plate girders with 16” mid-span camber. The building is positioned on the National Mall in Washington D.C. on the last remaining plot of land just beside the Washington Monument.

Our company has received the Washington Building Congress Craftsmanship Award for detailing over 4000 tons of steel on this project and the highly respected Star Award for Excellence in the Face of Adversity, which was presented to the project team leader, Mikolaj Zak, for the highest quality job that was done under the most difficult conditions.

Compudraft has also earned national recognition in the 2017 Innovative Design in Engineering and Architecture with Structural Steel awards program – IDEAS² – which were presented from the American Institute of Steel Construction (AISC). The category won was “Over $75 million” in constructed value.

We were also included the prestigious Tekla North America BIM Awards 2015, where Prodraft, Inc. was the recipient of the “Public” category award for our model on the NMAAHC.

Our work on this project was described in the Modern Steel Construction magazine on the November 2016 Issue explaining the complexity and innovation of the steel structure design and how all teams involved on the job coordinated to achieve time-efficient and precise solutions.